Patented in Canada, REV™ technology is an innovative drying method developed as an alternative to commonly used techniques such as freeze drying and air drying. The vacuum system lowers the evaporation point of water, allowing products to be dried at lower temperatures and in a shorter time.

In this process, drying begins from the center of the product and moves outward. The combination of vacuum and microwave energy results in uniformly dried products that retain their nutritional value, color, and aroma.

The low drying temperature helps preserve a high level of vitamins, minerals, and overall nutritional value, resulting in products that offer significantly greater nutritional benefits compared to those dried with conventional methods.

NutraREV™ dries different vegetable and fruit pieces without breaking them, making it highly suitable for the dehydration of organic materials that can roll.

A wide range of fruits, vegetables, meat and dairy products, spices, herbs, and grains can be efficiently and uniformly dried on the NutraREV™ platform.

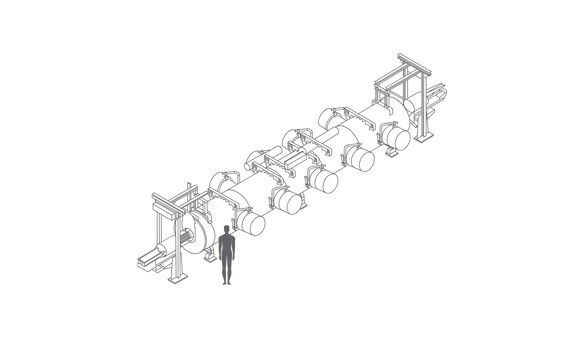

Raw materials are loaded into baskets and passed through a vacuum microwave tunnel in rotating drums to achieve the desired moisture content uniformly. During production, the combination of vacuum and radiant energy can be adjusted to achieve the desired end product characteristics.

Kullanım alanı: Büyük ölçekli, zincirleme kurutma

Mikrodalga Gücü: 100 kW

Frekans: 2450 MHz

Vakum: 25-300 Torr

Footprint: 15.3 x 3.8 x 4.6 m (LWH)

Kapasite: 91 kg/saat su giderme

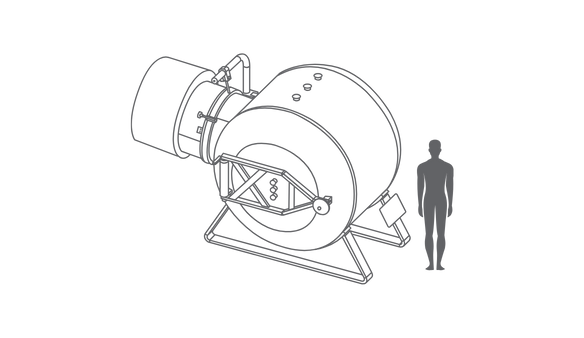

Kullanım alanı: Pazarlama ve ArGe denemeleri, test, küçük ölçek üretimler.

Mikrodalga Gücü: 10 kW

Frekans: 2450 MHz

Vakum: 12-300 Torr

Footprint: 2.4 x 1.8 x 3.1 m (LWH)

Kapasite: 9.1 kg/saat su giderme